Powder Coil

Marketing Strategy for Sustainability in Large-Scale Manufacturing

Role: Market Researcher

Time: Jan 2017 - May 2017 ,

Location: Chicago, IL

Problem

PowderCoil is a coil coating company. It is entering the market with a new disruptive technology that will steal market share by leapfrogging the competition with a superior product and significant operational cost savings for its customers. The current market for the coil coating company is mature with no innovation over 70 years. As a result, the market is slow and resistant to adopt new technology. To overcome this resistance in the market and be the future of pre painted metals, we are recommending objectives for the short, mid and long term.

Each year, the coil coating industry coats about 35 million tons of metal coil with liquid paint resulting in $10

billion in annual revenue. There are about 750 coil coating lines globally out of which there are 110 lines in North America. The last line built in United States was 7 years ago. There is no innovation in the last 70 years has led to complacency and resistance to change. Coil coating is a mature market. Although powder paint is superior to liquid paint, no one has devised a practical way of applying powder to metal coils until now with the emergence of a new disruptive technology.

HISTORY

PowderCoil technology was started in December 2004 under the company name First Precision LLC, (FP) an Indiana Limited Liability Company by Robert McShane, the Founder and CEO. The name was changed to Powder Coil in 2015. The initialplan of the company was to build the high speed PowderJet device which could coat Steel and Aluminum with dry paint i.e. powder. Initially there were five investors that enabled them to build the first applicator.

The PowderJet was proven to be an effective applicator but lacked operational precision. To improve the operational efficiency, the company leased a 42,000 sq-ft building and also hired engineers through funds received from Indiana Economic Development Commission.

The operational efficiency was improved but the overall economic climate was not favorable to gaining new investment. McShane did not give up and participated in UIC startup company in 2015 after which he met Donna Rockin of the Knapp Center of IIT . Through Donna Rockin, McShane met Mitch Saranow who was convinced to invest in the company.

With this investment, Powder Coil Technologies was able to invest in hiring mechanical engineers. With the help of mechanical engineer Manpreeth Singh and the mechanical department of IIT they completed virtual designing (in ANSYS) . In addition, at a small machine shop Gary Machinery, Griffith, Indiana they setup a test line to fully develop the PowderJet before commercial installation. PowderCoil technology is primed and ready for full commercial launch and market roll-out.

VALUE

PowderCoil is a mission and values driven company. It is important that our mission and values are felt through the implementation of our sales and marketing strategy.

ABOUT THE TECHNOLOGY

PowderCoil is a revolutionary high speed coil coating technology designed and developed to apply powder paint on a continuously moving strip of steel or aluminum. PowderCoil has the capability of painting versatile number of colors and patterns. The state of the art application and curing technology enables it to produce one of the best coil to coil pre-painted steels available in the current market. Powder application technology is specifically designed to replace continuous coil, spray gun technology. .

The PowderJet’s unique design has no moving parts, pneumatically applying powder paint directly to the moving metallic strip. The system precisely controls the volume and width of the powder emission to match the speed and size of the metallic strip. The metallic strip is coated on one or both sides while the film thickness is precisely controlled to customer specifications. The PowderJet utilizes focused line-source electrostatic charging technology which results in particulate ionization many times greater than gun systems. The applicator produces a 90% deposition factor that enables the PowderCoil system to meet cost and quality parameters comparable to any liquid coil coating operation

ULTIMATE GOAL

Our ultimate goal is the be “The Future of Pre-Painted Metals”. This business will be sustainable across North American and Global regions by providing environmentally significant and economically competitive platform for users, consumers, and designers of pre-painted metals. Our final mission is to demonstrate to the world that best in class products can be produced in a manner consistent with the needs of mankind without harming the environment in the process. We plan on breaking even within the first year of launching at EdCoat. In order to achieve our ultimate goal, we have set the following objectives:

AWARENESS OBJECTIVE

COMPETITIVE OBJECTIVE

Short term: After the successful launch of PowderJet Technology at the EdCoat test facility, we plan to target 30 customers in the Big 5 categories starting with building products and garage doors using EdCoat as sales channel.

Mid-term: Sell equipment and powder to existing Coil Coaters.

Long term: Sell equipment and paint to 200+ coil coating lines

within 15 years to achieve 30% market share of all pre-painted metals.

Our primary competitive objective is to protect our IP and proprietary technology through patents and copyright laws to prevent new entrants.

While at EdCoat we will establish the performance and viability of PowderJet solution and use customer testimonials and case studies to raise awareness on the benefits of PowderCoil. Increased awareness will help sell new equipment and powder to existing and new coil coaters. Use communication strategies and digital marketing to spread awareness of the benefits of PowderCoil both domestically and globally.

STRATEGY

TARGET MARKET

CUSTOMERS

ORIGINAL EQUIPMENT MANUFACTURES

This customer segment represents the end-users of pre-painted metals and are located furthest down the supply chain. These are the manufacturers of products that use a combination of pre-painted metals and post-painting with powder to complete and assemble the final products they deliver to the ultimate end-users. Currently most OEM’s use a combination of pre-painted and post-painted metals to assemble their products.

They understand the benefits of powder over liquid and would bemore inclined to try pre-painted metals with powder. They are the least resistant to change as they have not already invested in expensive liquid coil coating machines and understand the benefits of Powder.

EXISTING COIL COATER'S

This segment represents all of the existing coil coating lines in the US and around the world that have the potential to be retro-fitted with the new PowderJet technology. These existing coil coating lines are either independently owned companies that act as a toll processor for the OEM companies that require the use of pre-painted metal services or their are also existing coil coating lines owned by steel mills in an attempt to vertically integrate their services. Each existing coil coating line is unique and requires a different design and solution for retro-fitting as no two coil coating lines are exactly the same.

NEW COIL COATER'S

New coil coater segment represents customers that plan on constructing a brand new coil coating line. Although construction of new coil coating lines has slowed significantly in the US - there is much growth in developing nations like India and China. In the US, research shows that steel producing companies like SDI and NuCor steel are striving to vertically integrate steel producing and pre-painting in pursuit of higher margins.

COLLABORATORS

EDCOAT

It is an early visionary and pioneer in the metal industry, established in 1998. They provide pre painting service for all kind of metals including coil rolled, aluminum, stainless steel etc. Partnering with EdCoat provides powder coil an opportunity to use their facility to practically show the advantages of PowderJet technology and create a stream for getting OEM’s.

PIONEER POWDER

It is a private label proprietary in powder coatings . They have the ability to formulate powder for the customer specific needs. They have already agreed to partner with PowderCoil and also there is an agreement that the powder will be marketed under the trademark PowderBond. Also the owner of Pioneer Powder is one of the advisory board members.

PARKER POWDER

Manufactures powder handling equipment. They have an excellent technical ability. In addition, they have patents on manufacturing powder spray technology equipments, which makes them only suppliers for PowderCoil. Collaborating with this company would give PowderCoil an added advantage in the market.

COMPETITORS

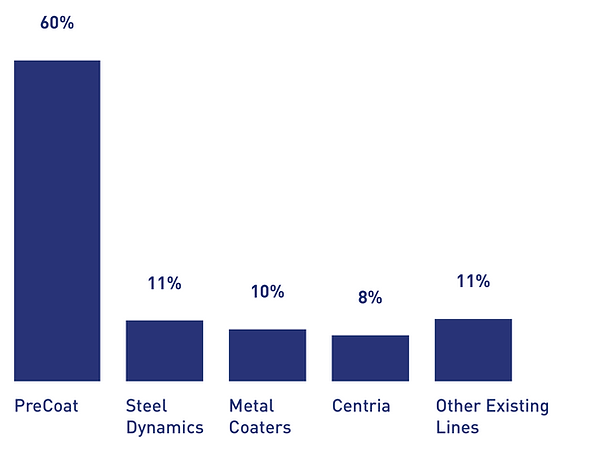

PowderCoil coating technology is unique and will revolutionize the pre-painted metal coil market. Although powder paint is superior to liquid paint, no one till date has devised a practical way of applying powder to metal coils. Thus, currently there is no competitors in powder coil coating industry. However, since there are substitutes of powder coil coating, there is a rivalry in existing pre-painted metal coating industry. The competitive scenarios of the top players in the coil coatings market include: Existing pre-paint (Liquid) coil coaters and Powder coating applicators utilizing contemporary “gun” technology. Therefore, the pre-painted metal coil coating industry rivalry is intense. Currently, PreCoat Metal is the dominant competitors in pre-paint industry. PreCoat has 15 coil coating lines and commands a 60% market share. Other competitors include Metal Coaters (10% of market share), Centria (8% of market share) and Steel Dynamics (11% of market share).

Due to the lack of innovation in the coil coating industry, PreCoat as the dominant player uses acquisitions and consolidation to seek new growth verticals. We can assume that with the launch of PowderCoil into the market, they will aggressively try to maintain their competitive position either by lowering their pricing, communication counter measures, reverse engineering of the PowderJet technology or through acquisition of the company.

MARKET SHARE OF COIL COATING INDUSTRY

CUSTOMER VALUE PROPOSITION: OEM

VALUE PROPOSITION

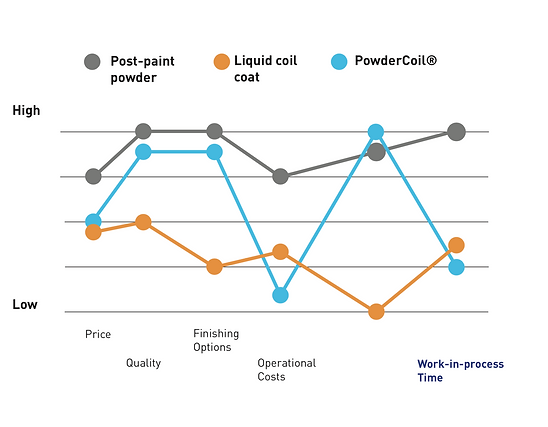

For OEM’s who want to improve manufacturing efficiency while improving product quality and finishing options, we offer a new pre-painted metal technology unlike anything else on the market, PowderCoil can lower operating costs through a new processing capability that can reduce cycle time from 5 weeks to 1 week

KEY VALUE ENHANCERS

-

7% cost reduction

-

Drastic cycle time reduction from 5 weeks to 1 week

-

Powder is higher quality and more durable paint solution

-

More flexibility with materials including anti- microbial coatings and reflective options

-

Can offer more flexible material and finishing options to designers and consumers.

CUSTOMER VALUE PROPOSITION: EXISTING COIL COATERS

VALUE PROPOSITION

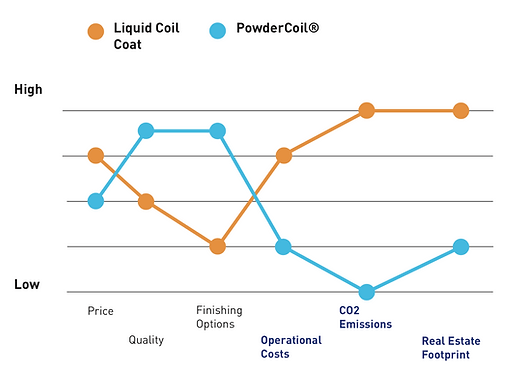

For existing coil coaters, who want to do it cheaper and better, we offer a new technology that can lower operating costs by 30%, CO2 emissions by 100% while offering a higher quality product with more flexibility finishing options quicker color change options.

KEY VALUE ENHANCERS

-

30% reduction in operating costs

-

100% reduction in CO2 exhaust

-

Environmentally sustainable with no volatile organic compounds

-

Increase ability to gain customers by offering new competitive advantage

-

Offer new, better product to their customers

-

Fast color change and flexible color options

-

Less maintenance

CUSTOMER VALUE PROPOSITION: NEW COIL COATERS

VALUE PROPOSITION

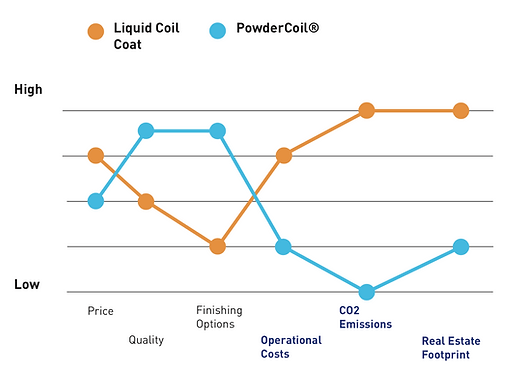

For firms interested in producing a new

coil coating line, PowderCoil offers a new technology in pre-painted metals that reduces total initial investment costs by 40% and unlike current liquid coating lines, our technology is 100% environmentally friendly with no CO2 output.

KEY VALUE ENHANCERS

• 40% less capital intensive

• Less real estate needed: 300ft vs 900ft

• 100% environmentally sustainable

• No air or water treatment systems needed • Superior product

• Innovative new vertical line design options

STRATEGY AND ANALYSIS

OVERALL STRATEGY

The overall strategy for PowderCoil is to steal market share from existing market leaders by leapfrogging ahead with superior technology and a superior product. To do this we will target customers who are uniquely positioned to benefit from PowderJet’s core capabilities while educating the rest of the market/industry to the benefits and performance of our superior technology. We will achieve our primary objective by

first targeting OEM’s through EdCoat channel. Once we are a proven technology in the industry we will raise awareness through OEM channels then we will sell equipment and powder to existing and new coil coaters. The OEM’s market is key in creating a PULL marketing strategy for the other two market segments. Once the OEM’s discover the PowderCoil solution exists they will demand it from their existing pre-painted metal supplier. Thus, early conversion of the OEM market will exponentially drive sales through the rest of the customer segments.

PULL STRATEGY

In the OEM segment, we will initially target the building products business. This includes building panels and garage doors. They are the largest segment in the OEM category and have a healthy contribution margin to the business. The building products business closely follows the overall health of the US economy and the housing market. The US, and IL, is seeing growth in the housing industry especially in buildings that are more green certified. This is a good match for PowderCoil.

PUSH STRATEGY

The existing coil coater and new coil coating market will be strategically targeted with direct marketing through the tactics listed later in the report.

KEY ISSUES ADDRESSED

Does it work?

In order to adopt a new technology, customers must first know if it works. We can address these issues through the following ways:

-

Editorial reviews by technical experts

-

Positive case studies

-

Sales at EdCoat

-

Prospective customer list

Is it better?

We must demonstrate the product superiority of not only the manufacturing process but of the end product itself.

• Editorial reviews by technical experts • Published results of testing and

performance

• Positive case studies

• Customer testimonials

COMMUNICATION STRATEGY

Speaking Engagements

Previous speaking engagements and visits to trade conferences have proven to be effective marketing channels. We were not able to capitalize on these opportunities without a viable product ready to ship. We are confident that once the product is ready and we market through industry channels- it will open many new doors.

Workshops with Educational Materials

We can use the time at the EdCoat facility to conduct workshops with the staff to inform on the unique benefits of working with PowderCoil. We can develop educational materials and take-aways to lengthen the impression and deepen the impact with our customers and their employees.

Editorials and Whitepapers

In order to inform the market and create inbound sales, it will be key to publish articles and white papers in all the major metal and coil coating magazines. The main ones are:

-

American Metal Market

-

Metal Center News

-

Powder Coating Magazine

The goal of the digital marketing strategy is to compliment the overall direct marketing strategy online to make content available all over the world. Because PowderCoil will appeal to many international customers who we will not be able to reach through our traditional direct marketing channels - we must make information available online. Through online channels we can also drive awareness of the PowderCoil brand online and establish a customer lead pipeline through the website. To do this, we will execute the following objectives:

DIGITAL MARKETING

DIGITAL MARKETING

-

Re-design the PowderCoil website to reflect the company’s values and branding around innovation, environmentally friendly manufacturing and industry expertise. We can clearly highlight the benefits and value of pre-painting with powder as well as create many opportunities for customers to engage with and learn about PowderCoil.

-

Bio of Robert McShane and advisory board emphasizing industry expertise.

-

Allow space for case studies and customer testimonials.

-

Use of blog to demonstrate industry expertise. Blogs written by Bob as well as commissioning other industry experts to comment on benefits, performance and viability of PowderCoil technology.

-

Make use of white papers and excel tools available for free download if users supply email address and company names.

Website Prototype

Design Principles

New homepage should reflect values of PowderCoil like innovation and quality. Use of imagery should convey technical nature of the product and text should reflect key messaging strategies. Call -to-action buttons on homepage allow quick access to important content.